RoboSAPIENS

Redefining the future of robotics trustworthy adaptation

Self-Adapting

Robots

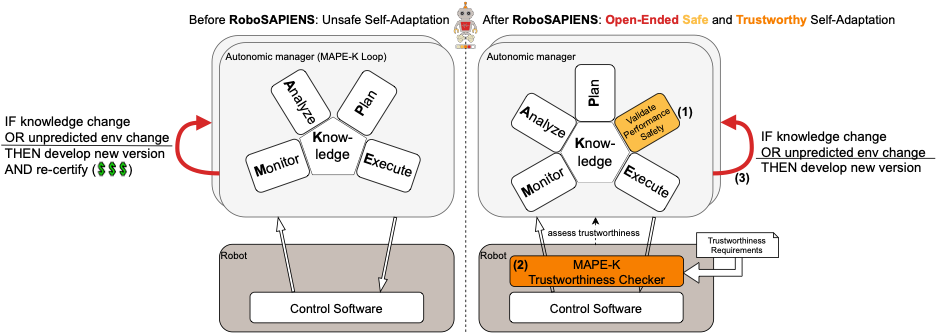

RoboSAPIENS will develop the underlying technologies which enable robots to fully autonomously adapt their controllers and configuration settings to accommodate for unknown changes and variations while ensuring trustworthiness.

What RoboSAPIENS wants to achieve

Enable Open-Ended Adaptation

Enhance Safety Assurance

Reduce Task Uncertainty with Deep Learning

Assure

Trustworthiness

How will we do it?

RoboSAPIENS will extend techniques such as MAPLE-K (Monitor, Analyze, Plan, Legitimate, Execute, Knowledge) and Deep Learning to set up generic adaptation procedures and also use an SSH dimension. RoboSAPIENS will demonstrate this trustworthy robotic self-adaptation on four industry-scale use cases centered around an industrial disassembly robot, a warehouse robotic swarm, a prolonged hull of an autonomous vessel, and human-robotic interaction.

Real world testing

The project isn’t staying in the lab. We’ll test these smart, trustworthy adaptations in four real industrial settings:

We plan to reach TRL4, which means working prototype-level tech that’s tested in realistic conditions.