Dynamic Risk Model: Adaptive Human–Robot Collaboration in Manufacturing (Fraunhofer IFF)

Challenge

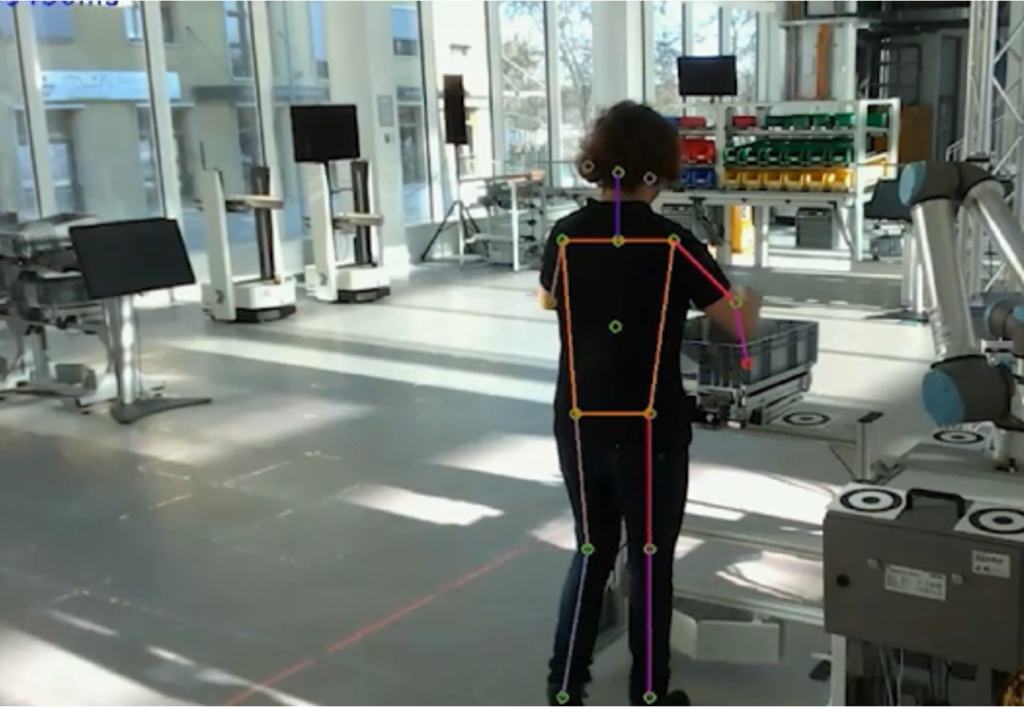

In the Fraunhofer IFF “Elbfabrik”, a collaborative robot (cobot) assists in operating a tool-processing machine. However, existing safety standards require a full stop whenever a human enters the workspace. This static approach to risk management limits flexibility and productivity in modern, reconfigurable production environments.

RoboSAPIENS Solution

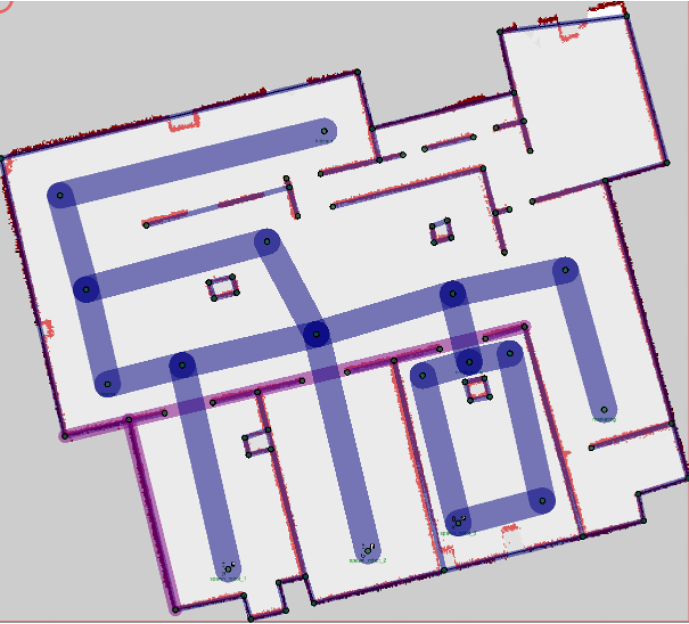

Fraunhofer IFF introduces an adaptive safety system that adjusts the robot’s speed instead of stopping entirely. Using multi-angle cameras for human pose estimation, the cobot calculates safe distances in real time and adapts movement accordingly. The MAPLE-K architecture ensures safety decisions are transparent, traceable, and compliant with defined operational limits. Runtime trustworthiness checkers evaluate system reliability and integrate findings into a digital twin, enabling live monitoring and visualisation of human–robot interactions.

Impact

The first implementation demonstrated a clear improvement in efficiency and process continuity. The robot can maintain productivity without compromising human safety, and the digital twin allows for transparent verification of adaptive decisions.

Future Outlook

This approach could pave the way for scalable adaptive safety frameworks across entire production floors, especially in small and medium-sized enterprises (SMEs). Future work will focus on improving camera positioning robustness and developing standards that can certify AI-driven safety mechanisms in collaborative robotics.

Social Sciences & Humanities Insights

RoboSAPIENS integrates Social Sciences and Humanities (SSH) research to ensure that adaptive robotics evolves in line with human values, ethics, and workplace realities. SSH activities explores how people interact with, trust, and accept robotic systems in each industrial context.

The Fraunhofer IFF Dynamic Risk Model use case SSH analysis concentrates on human–robot collaboration on the factory floor, exploring trust, perceived safety, and the role of adaptive systems in maintaining worker confidence.